Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

Categories

-

Shimano XT M8100 2 piston disc brakes199,95 € 259,95 €

Shimano XT M8100 2 piston disc brakes199,95 € 259,95 €

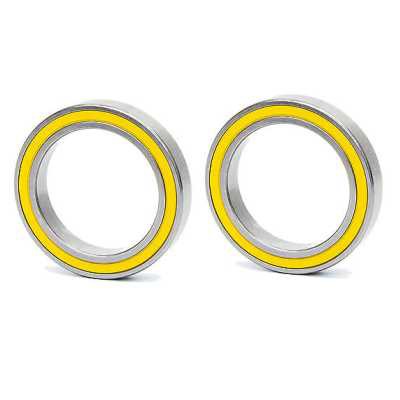

Ceramic bearings vs steel bearings

Steel bearings and ceramic bearings are two types of bearings used in cycling. Both types of bearings have their own advantages and disadvantages, and choosing the appropriate bearing type depends on the specific needs of the application.

Differences between steel and ceramic bearings:

Steel bearings are made of carbon steel or stainless steel. They are the most common type of bearing and are relatively inexpensive. Steel bearings have good corrosion and wear resistance, and can withstand heavy loads. They are manufactured in different qualities depending on the perfection of the roundness of the balls and the hardness of the steel used. The greater the roundness and the greater the hardness, the more efficient the bearing will be.

Ceramic bearings, on the other hand, are made of ceramic materials, such as alumina or silicon nitride. They are more expensive than steel bearings, they are very hard materials, but they are usually more fragile to impacts. It must be taken into account that in the event of an impact the balls act like a wedge against the concave race, which normally causes the race to split, since it is not capable of deforming as steel does.

Aspects that affect efficiency:

As we have said, the greater the roundness and the greater the hardness, the more efficient the bearing will be. However, steel bearings also have higher friction than ceramic bearings, due to the metal-metal interaction that occurs between the metal atoms of the balls and races, which reduces the efficiency of the bearing. In ceramic bearings this metal-metal interaction does not occur, so with equal quality (roundness and hardness) ceramic bearings are always more efficient.

To minimize metal-metal interaction, dense and sticky lubricating greases are used that constantly "wet" both surfaces, which also causes a braking effect due to the drag of that grease. In ceramic bearings it is not necessary to apply grease (or very little and not very dense is applied) so they again gain in efficiency. We have all seen ceramic hubs or pulleys rotating for many minutes without stopping, while with steel bearings they stop after a few revolutions due to this braking effect.

An increasingly common intermediate option to avoid this metal-metal interaction are ceramic hybrid bearings. In these bearings the races are metal but the balls are ceramic. With this, the metal-metal interaction disappears, we save costs as the steel races are much cheaper, and we gain impact resistance.

In addition, ceramic bearings offer a number of other advantages, such as:

- Greater corrosion resistance: Ceramic bearings are more resistant to corrosion than steel bearings, making them ideal for applications in harsh environments.

- Higher temperature resistance: Ceramic bearings can withstand higher temperatures than steel bearings, making them ideal for high temperature applications.

Advantages and disadvantages of steel bearings:

Advantages:

- Relatively inexpensive.

- Good resistance to corrosion and wear.

- They can withstand heavy loads.

- They withstand impacts better.

Disadvantages:

- Greater friction.

- Corrosion and oxidation problems.

Advantages and disadvantages of ceramic bearings:

Advantages:

- Less friction.

- Greater resistance to corrosion.

- Greater temperature resistance.

Disadvantages:

- More expensive.

- Lower impact resistance.

What type of bearing is best?

The answer to this question depends on the specific needs of the application. If the application requires a bearing with low friction, corrosion resistance and temperature resistance, then a ceramic bearing is the best choice. However, if the application requires a bearing with good vertical load resistance, then a steel bearing is the best option.

In bicycles, ceramic bearings are increasingly used in high-performance applications such as wheels, pulleys, bottom bracket cups and pedals. Ceramic bearings can help improve bike efficiency and reduce wear, which can translate into improved performance and longer bike life.

Finally, a practical note from TiendaMTB.com: if you ride in areas where it rains a lot and is usually muddy and you don't have much budget, it is undoubtedly much better to buy steel bearings and change them every year, rather than stretching the life of some ceramics. A new steel bearing works better than a dirty ceramic one. You can also try removing the ceramic bearing covers and cleaning it thoroughly with a 3in1 type spray until you notice that it spins again without any friction.

Buscar en Blog

Archivo del Blog

Blogs recientes

-

Wheel sizes and circumference

Wheel sizes and circumference

Wheel sizes and circumference table for bicycle wheels. You can use them to configure your bicycle computer or your...feb 12, 2025 Read more -

eBike motors 1: Bosch Generation 2

eBike motors 1: Bosch Generation 2

The Bosch Gen 2 motor represented a significant advance in electric bicycle technology. Introduced in 2014, this...feb 12, 2024 Read more -

Ceramic bearings vs steel bearings

Ceramic bearings vs steel bearings

Steel bearings and ceramic bearings are two types of bearings used in cycling. Both types of bearings have their own...ene 16, 2024 Read more -

Wax chain lubricants

Wax chain lubricants

Wax bicycle chain lubricants are an increasingly popular choice among cyclists. These lubricants offer a number of...ene 15, 2024 Read more -

The lightest mountain bike components in TiendaMTB.com

The lightest mountain bike components in TiendaMTB.com

Although sometimes we are considered obsessed with weight, only a biker knows what it costs to move every gram we...dic 23, 2019 Read more -

What is the offset of a chainring?

What is the offset of a chainring?

nov 8, 2019 Read more -

New team helmet for 2019

New team helmet for 2019

The Extreme E2 is the helmet selected by TiendaMTB.com team for 2019 competitions. The reason: high quality, excelent...mar 11, 2019 Read more -

How to install tubeless presta valves

How to install tubeless presta valves

As a distributor of X-Sauce products, at TiendaMTB.com we would like to send you the manufacturer's recommendations...sep 7, 2018 Read more -

How to change the BB30 bearings

How to change the BB30 bearings

After these days of so much rain and mud it is very important that we check the condition of the bearings of the...mar 6, 2018 Read more -

How to remove a SRAM BB30 cranks

How to remove a SRAM BB30 cranks

Removal of SRAM cranks with BB30 axle from your bike (both MTB and road) is a very easy process that anyone can do....mar 5, 2018 Read more